-

-

-

-

-

-

Contact

Product

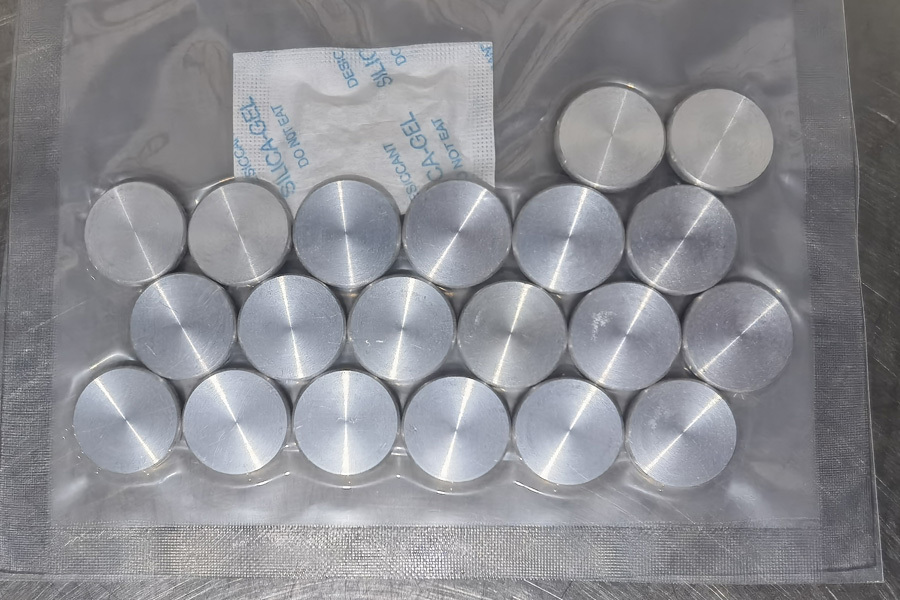

Tungsten-based high specific gravity alloy

Category: High specific gravity

key word : Tungsten-based high specific gravity alloy

Mobile:+86-13903792565

Mobile:+86-13503495123

Product Introduction

High density tungsten alloy is a kind of tungsten matrix (W content 85-99%), and add Ni, Cu, Co, Mo, Cr and other elements of the alloy.

According to the composition characteristics and uses of the alloy is divided into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, and other major series, its density is as high as 16 .5-19.0g/cm3, which is called high specific gravity alloy.

It also has a series of excellent characteristics, with large specific gravity: general specific gravity of 16.5-18.75g/cm3, high strength: tensile strength of 700-1000Mpa, strong ability to absorb rays: its ability is 30-40% higher than lead, and its thermal conductivity is large: 5 times that of die steel; Small thermal expansion coefficient: only 1/2-1/3 of iron or steel, good electrical conductivity; It has good weldability and workability. In view of the high specific gravity alloy has the above excellent function, it is widely used in aerospace, aviation, military, oil drilling, electrical instrumentation, medical and other industries.

The use of high proportion tungsten alloy is very extensive, mainly used in the following aspects:

Mechanical and automotive industries: High specific gravity tungsten alloys are used in racing and automotive counterweights to optimize performance and balance control.

Aerospace and Defense Industries: Due to their high density and good mechanical strength, tungsten alloys play an important role in the aerospace and defense industries, such as counterweights for aircraft and missiles.

Medical industry: High specific gravity tungsten alloy is used for shielding materials of medical devices, such as collimators, wing-shaped protection components and anti-penumbra blocks, etc. because of its excellent shielding performance.

Electrical industry: In the electrical industry, high-density tungsten alloys are used for electrical riveting machines and contact materials, which have the characteristics of resistance to electrical corrosion and oxidation.

Sports equipment: Due to its high density and small volume characteristics, high specific gravity tungsten alloy is used for golf head, tennis racket, badminton racket and other sports equipment weight, to increase momentum and reduce vibration.

Other applications: including balance weights and flying hammers for machinery; weighting rods used in oil and other drilling industries; clock pendulum; shockproof knife bar, balance weight ball, etc.; vibrators used in mobile phones, game consoles, etc.; ballast weights and counterweight parts for navigation, sailing ships, etc; gyroscopes used in aerospace, aircraft counterweights, automatic watches, heavy hammers, knife holders, high crankshaft counterweights for small chain saw engines, electrodes for EDM and electrochemical machine tools, etc.

High specific gravity tungsten alloys are widely used in many industries due to their unique physical properties, such as high density, good mechanical strength, and easy processing.

What if you have more needs?

Please leave your demand information and we will reply to you in time!

Luoyang Tongfang Technology Co., Ltd.

Mobile:+86-13503495123

Mobile:+86-13903792565

E-mail:lytongfangkeji@163.com

Address: Li Wan Xingguang Science Park, Gu County Town, Yanshi District, Henan Province

Copyright 2024 Luoyang Tongfang Technology Co., Ltd. This website supports ipv6