-

-

-

-

-

-

Contact

Product

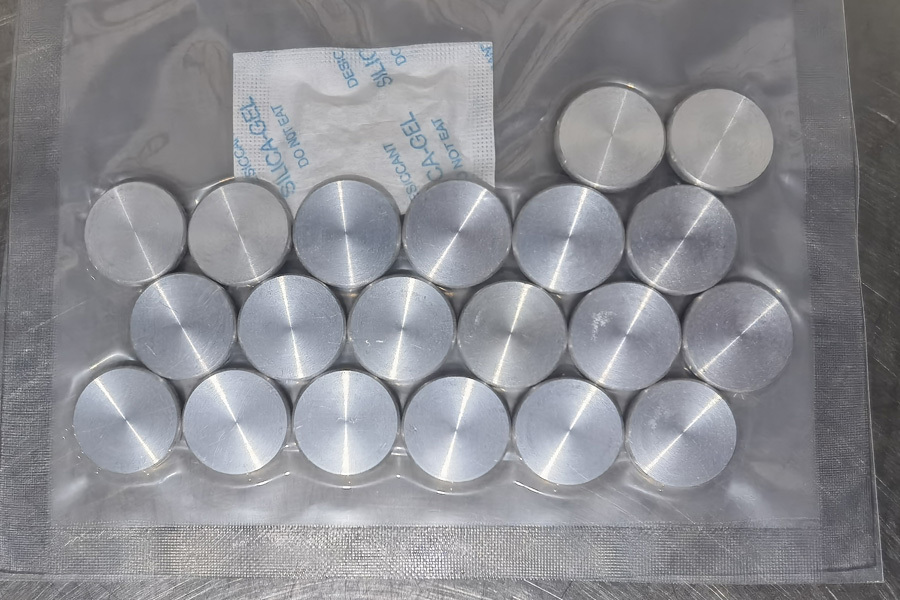

Copper Tungsten Carbide Contact

key word : Copper Tungsten Carbide Contact

Mobile:+86-13903792565

Mobile:+86-13503495123

| Name | Diameter | Thickness | Thickness of copper-clad layer |

| Copper Tungsten Carbide Contact | 10mm--50mm | 2mm-10mm | 0.3mm-10mm |

Copper-tungsten-tungsten-carbide alloy is a high-performance composite material that combines the characteristics of copper, tungsten and tungsten carbide, such as the high melting point, high boiling point, high strength and high hardness of tungsten, as well as the electrical conductivity and thermal conductivity of copper. And low contact resistance. The microstructure of this alloy material is uniform and dense, and exhibits excellent mechanical properties and arc burning resistance.

Copper-tungsten-tungsten-carbide alloy is widely used in many fields because of its good electrical conductivity, thermal conductivity, high temperature resistance, arc ablation resistance, high strength and high hardness. These areas include aerospace, electronic information, defense industry, electrical and mechanical processing. In addition, the alloy is also used in the manufacture of high-voltage electrical switch contacts, rocket nozzle throat lining, tail rudder and other high-temperature components, as well as electrical processing of the electrode, high-temperature mold.

Copper tungsten carbide contact is a high-performance electrical contact material, with the following significant advantages:

High arc ablation resistance: Because the copper-tungsten-tungsten carbide alloy combines the high melting point of tungsten and the high hardness of tungsten carbide, the contact exhibits excellent arc ablation resistance and is suitable for electrical contact materials for high-voltage electrical switches.

High Electrical and Thermal Conductivity: The addition of copper significantly increases the electrical and thermal conductivity of the alloy, making it excellent for electronic packaging and thermal management applications.

Excellent contact welding resistance: The composition and microstructure of the alloy help to improve the contact welding resistance and reduce the welding tendency during electrical contact.

Lower cut-off value: Suitable for high short-circuit currents in vacuum contactors, closed-circuit systems and reclosers, and can withstand more than one million switching cycles.

High strength and high hardness: The addition of tungsten carbide provides high strength and high hardness, so that the contact remains stable under mechanical stress.

Easy to process: Compared with pure tungsten or tungsten carbide, copper-tungsten-tungsten carbide alloy is relatively easy to process and can be made into parts of various shapes and sizes.

Good wear resistance and corrosion resistance: tungsten copper contacts show good wear resistance and corrosion resistance, in the field of electrical processing, electronic packaging has a wide range of applications.

Comprehensive improvement of electrical wear resistance: by adding elements and conductive ceramics, the oxidation resistance of the material is improved, and the electrical wear resistance of the material is improved.

Suitable for high-load switching: Tungsten copper contacts can be used for high-load switchgear, including high-voltage and medium-voltage generator circuit breakers.

Low thermal expansion coefficient: The low thermal expansion coefficient of tungsten copper alloy helps to maintain the stability of contact size under temperature changes.

These advantages make copper-tungsten-tungsten-carbide contacts popular in power systems, high-voltage electrical switches, electrical machining equipment, and other applications that require high-performance electrical contact materials.

What if you have more needs?

Please leave your demand information and we will reply to you in time!

Luoyang Tongfang Technology Co., Ltd.

Mobile:+86-13503495123

Mobile:+86-13903792565

E-mail:lytongfangkeji@163.com

Address: Li Wan Xingguang Science Park, Gu County Town, Yanshi District, Henan Province

Copyright 2024 Luoyang Tongfang Technology Co., Ltd. This website supports ipv6