-

-

-

-

-

-

Contact

Product

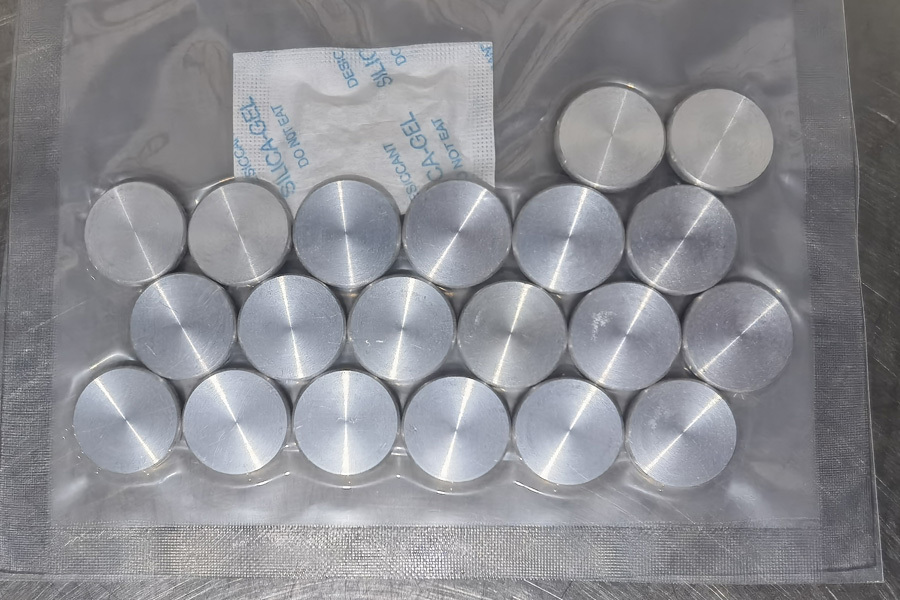

Tungsten copper alloy

Category: Tungsten copper alloy, tungsten silver alloy

key word : Tungsten copper alloy

Mobile:+86-13903792565

Mobile:+86-13503495123

| Name | Diameter | Thickness | |

| tungsten copper alloy | 10mm--50mm | 2mm-10mm |

Product Introduction

Tungsten copper alloy is an alloy composed of tungsten and copper. The copper content of commonly used alloys is 10% to 50%. The alloy is made by powder metallurgy method, which has good electrical and thermal conductivity, good high temperature strength and certain plasticity. At very high temperatures, such as above 3000 ℃, the copper in the alloy is liquefied and evaporated, absorbing a large amount of heat and reducing the surface temperature of the material, so this kind of material is also called metal sweating material. Tungsten copper alloy has a wide range of uses. It is mainly used to manufacture high-voltage electrical switch contacts and rocket nozzle throat lining, tail rudder and other high-temperature components that resist arc ablation. It is also used as an electrode for electrical processing, high-temperature molds and other occasions that require high electrical and thermal conductivity and high-temperature use.

Advantages and Application of Tungsten Copper Alloy

Resistance welding electrode: combines the advantages of tungsten and copper, high temperature resistance, arc ablation resistance, high strength, specific gravity, good electrical and thermal conductivity, easy cutting, and has the characteristics of sweating cooling. Because of the high hardness, high melting point and anti-adhesion characteristics of tungsten, tungsten copper alloy is often used to make projection welding and butt welding electrodes with certain wear resistance and high temperature resistance.

Electric spark electrode: when the mold made of tungsten steel and high temperature resistant super hard alloy needs electric erosion, the ordinary electrode loss is large and the speed is slow. The high electric corrosion rate, low loss rate, accurate electrode shape and excellent processing performance of tungsten copper can ensure that the accuracy of the processed parts is greatly improved.

High-voltage discharge tube electrode: When the high-voltage vacuum discharge tube is working, the temperature of the contact material will rise to several thousand degrees Celsius within a few tenths of a second. The tungsten copper high ablation resistance, high toughness, good electrical conductivity, thermal conductivity can provide the necessary conditions for the stable work of the discharge tube.

Electronic packaging materials: both the low expansion characteristics of tungsten, but also has the high thermal conductivity of copper, its coefficient of thermal expansion and thermal conductivity can be changed by adjusting the composition of the material, so as to expand the use of materials to provide convenience.

Copper-tungsten electrical contacts represent symbols, chemical composition and physical and mechanical properties.

Electrical contact | Representative symbol | Chemical composition/% | Physical and mechanical properties | ||||||||

Cu | Ag | Total impurity ≤ | W | Density | Hardness | Resistivity | Conductivity | Bending strength | |||

Copper-tungsten series | Copper Tungsten (50) | CuW(50) | 50 2.0 |

| 0.5 | Allowance | 11.85 | 115 | 3.2 | 54 |

|

Copper Tungsten (55) | CuW(55) | 45±2.0 |

| 0.5 | Allowance | 12.30 | 125 | 3.5 | 49 |

| |

Copper Tungsten (60) | CuW(60) | 40 2.0 |

| 0.5 | Allowance | 12.75 | 140 | 3.7 | 47 |

| |

Copper Tungsten (65) | CuW(65) | 35 2.0 |

| 0.5 | Allowance | 13.30 | 155 | 3.9 | 44 |

| |

Copper Tungsten (70) | CuW(70) | 30±2.0 |

| 0.5 | Allowance | 13.80 | 175 | 4.1 | 42 | 790 | |

Copper Tungsten (75) | CuW(75) | 25±2.0 |

| 0.5 | Allowance | 14.50 | 195 | 4.5 | 38 | 885 | |

Copper Tungsten (80) | CuW(80) | 20±2.0 |

| 0.5 | Allowance | 15.15 | 220 | 5.0 | 34 | 980 | |

Copper Tungsten (85) | CuW(85) | 15 2.0 |

| 0.5 | Allowance | 15.90 | 240 | 5.7 | 30 | 1080 | |

Copper Tungsten (90) | CuW(90) | 10 2.0 |

| 0.5 | Allowance | 16.75 | 260 | 6.5 | 27 | 1160 | |

What if you have more needs?

Please leave your demand information and we will reply to you in time!

Luoyang Tongfang Technology Co., Ltd.

Mobile:+86-13503495123

Mobile:+86-13903792565

E-mail:lytongfangkeji@163.com

Address: Li Wan Xingguang Science Park, Gu County Town, Yanshi District, Henan Province

Copyright 2024 Luoyang Tongfang Technology Co., Ltd. This website supports ipv6