-

-

-

-

-

-

Contact

Product

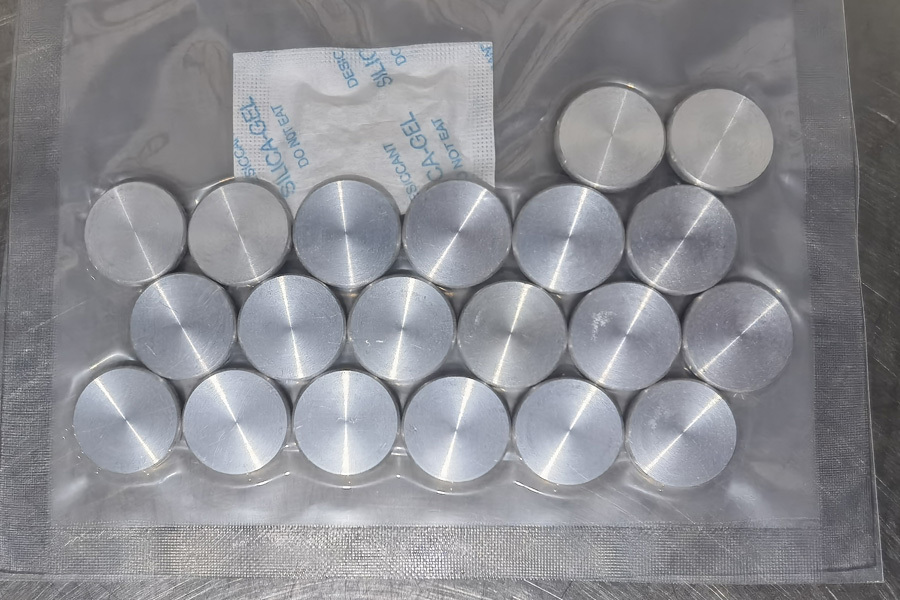

Molybdenum powder

key word : Molybdenum powder

Mobile:+86-13903792565

Mobile:+86-13503495123

Molybdenum (Molybdenum), the fifth period of the periodic table of the elements in group 6 (chromium group) transition metal elements. Element symbol Mo, atomic number 42, relative atomic mass 95.95. The relative density is 10.28g/cm³, the melting point is 2622 ℃, and the boiling point is 4825 ℃. The resistivity is 5.2x 10 but Ω · m(20°C).

Molybdenum has the characteristics of high strength, high hardness and excellent mechanical properties, and can still maintain high strength and high hardness at high temperature. Molybdenum is mainly used for steelmaking, and alloy steels doped with molybdenum have high strength, high toughness, outstanding heat resistance and corrosion resistance. Metal molybdenum is widely used in electronic tubes, transistors, rectifiers and other electronic devices.

The important compounds of molybdenum are molybdenum oxide, molybdenum sulfide, molybdate and molybdenum acid salt. Molybdenite (the main component of molybdenum disulfide) exists in nature. The high-temperature oxidized molybdenite is molybdenum oxide, which is then reduced by hydrogen or aluminothermic method to produce elemental molybdenum. Mainly used for special alloys, electrodes and catalysts. It is an essential trace element for human body.

| Molybdenum |

Density |

Melting Point |

Boiling Point |

Resistivity |

| Mo |

10.28g/cm3 |

2622 ℃ |

4825 ℃ |

5.2X10⁻⁸Ω·m(20℃) |

Industrial use

electrode for melting glass: Molybdenum is a good electrode material because of its high strength at operating temperatures and its good electrical conductivity, and the possible formation of molybdenum oxides does not discolor most glasses.

Heating furnace components:The high thermal strength of molybdenum makes it widely used in vacuum heating furnaces, neutral or reducing atmosphere heating furnaces, such as the production of heating elements, reflectors and boats.

Electrical and Electronic Components:Molybdenum wires are good conductors and are widely used in incandescent bulbs to support tungsten wires. Radio vacuum tubes, X-ray tubes, and many electronic devices require molybdenum to produce components with high thermal strength.

Moulds:One of the more important uses of TZM molybdenum-based alloys is in the production of cores and dies for brass, aluminum and steel die castings. Even some zinc die castings use TZM mold effect is very good. TZM alloy casting mold has the advantages of high thermal strength, good heat dissipation, and thermal crack resistance.

hot processing mold:TZM molybdenum-based alloy has high thermal strength, so it can be used to make forging dies, stamping dies and punching rods.

Medical use:Molybdenum -99 is one of the radioactive isotopes of molybdenum and is used in hospitals to prepare technetium -99. Technetium -99 is a radioactive isotope that can be used by patients for visceral organ imaging. The molybdenum -99 used for this purpose is usually absorbed with alumina powder and stored in a relatively small container. When the molybdenum -99 decays, technetium -99 is formed. The technetium -99 can be removed from the container and distributed to the patient when needed.

What if you have more needs?

Please leave your demand information and we will reply to you in time!

Luoyang Tongfang Technology Co., Ltd.

Mobile:+86-13503495123

Mobile:+86-13903792565

E-mail:lytongfangkeji@163.com

Address: Li Wan Xingguang Science Park, Gu County Town, Yanshi District, Henan Province

Copyright 2024 Luoyang Tongfang Technology Co., Ltd. This website supports ipv6