-

-

-

-

-

-

Contact

Product

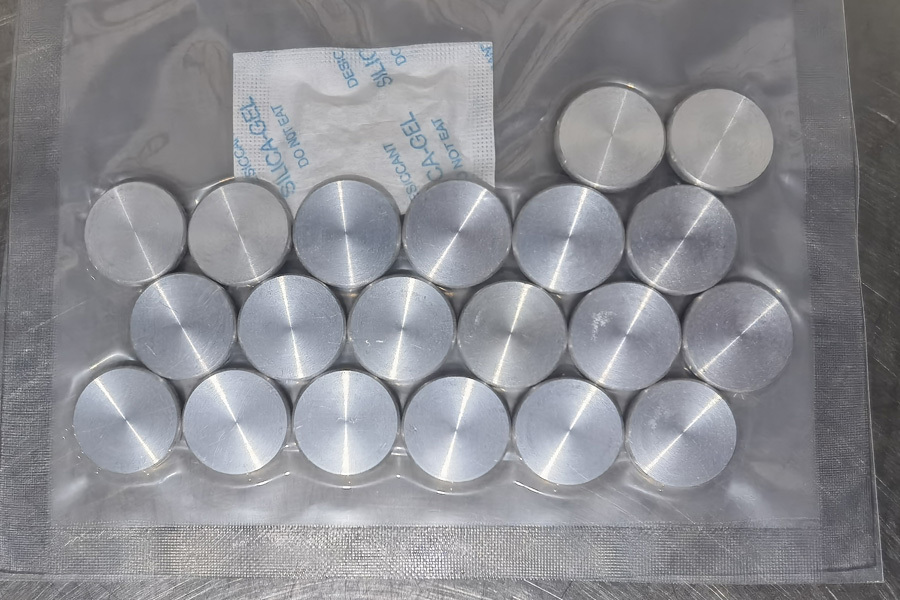

Tungsten Carbide Copper

Category: Tungsten carbide copper alloy, tungsten carbide silver alloy

key word : Tungsten Carbide Copper

Mobile:+86-13903792565

Mobile:+86-13503495123

| Name | Diameter | Thickness | |

| Tungsten Carbide Copper | 10mm--50mm | 2mm-10mm |

Tungsten carbide copper alloy is the use of high quality tungsten carbide powder and oxygen-free copper powder, the application of pressing molding-high temperature sintering-copper infiltration process to ensure product purity and accurate ratio, fine organization, excellent performance, good arc breaking performance, good electrical conductivity, good thermal conductivity, small thermal expansion. High temperature resistance, arc ablation resistance, high strength, specific gravity, electrical conductivity, good thermal conductivity, easy cutting, and has the characteristics of transpiration cooling, as a vacuum contact material, electrode material.

Advantages and uses of tungsten carbide copper

Tungsten carbide copper alloy is a special alloy material, which combines the excellent characteristics of metal tungsten and copper, with high hardness, high strength, high temperature resistance, arc ablation resistance and other characteristics. These characteristics make tungsten carbide copper alloys widely used in many fields. Especially in the contact material of the vacuum switch tube, the tungsten carbide copper alloy shows its unique advantages. The application of this material benefits from its excellent electrical and thermal conductivity and moderate density, making it an ideal choice for electrical alloys for high-voltage switches. In addition, tungsten carbide copper alloy is also widely used in military high temperature resistant materials, rocket nozzle throat lining, tail rudder and other high temperature components, electrical processing electrodes, microelectronic materials, high temperature molds and other occasions requiring electrical and thermal conductivity and high temperature use. It covers aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment and other industries.

Specific to the application of tungsten carbide copper alloy in the vacuum switch tube contact material, this material can withstand the impact of high voltage and current, and has good arc ablation resistance, ensuring the stable operation and safe use of electrical equipment. In addition, tungsten carbide copper alloy also has excellent mechanical wear resistance, which is particularly important in applications such as oil-immersed switches that need to withstand high impact pressures. Therefore, the application of tungsten carbide copper alloy not only improves the performance and life of electrical equipment, but also provides important technical support for industrial production and daily life.

What if you have more needs?

Please leave your demand information and we will reply to you in time!

Luoyang Tongfang Technology Co., Ltd.

Mobile:+86-13503495123

Mobile:+86-13903792565

E-mail:lytongfangkeji@163.com

Address: Li Wan Xingguang Science Park, Gu County Town, Yanshi District, Henan Province

Copyright 2024 Luoyang Tongfang Technology Co., Ltd. This website supports ipv6